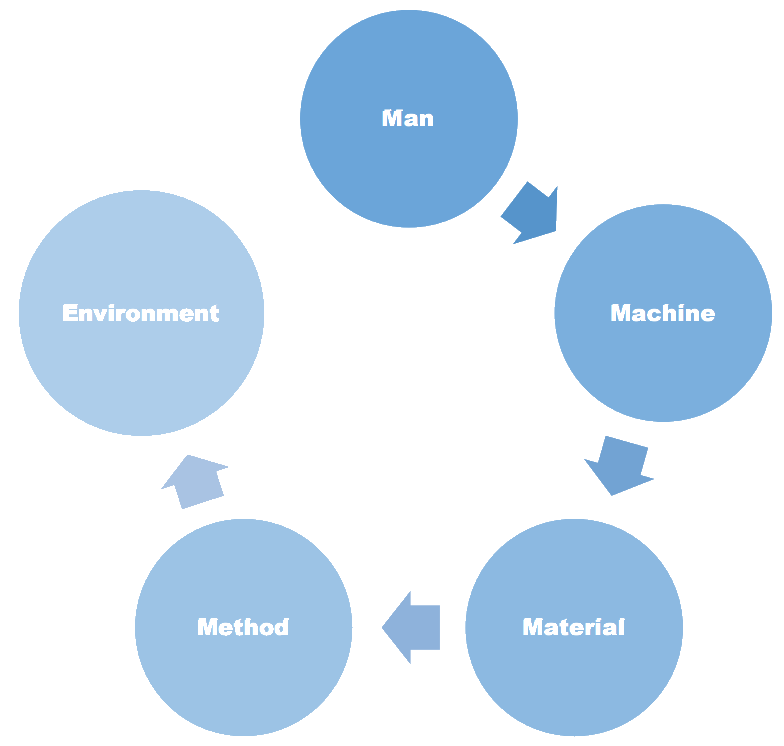

4M1E In Façade QC

- Man --- Features of character? Professional ability? Work attitude?Understanding of product quality?

- Machine --- Equipment is working properly? Suitable tools?Tools regular calibration and inspection?

- Material --- Form a complete set of materials? Raw material qualified? Semi-finished productqualified? Accessories qualified? Finished product qualified?

- Method --- Correct production drawings? ITP? Correct quality plan? Correct rules and regulations?

- Environment --- Suitable warehouse? Dust free room for structural sealant?Semi-finished and finished products protection? Suitable curing environment?

Façade QC Service.

- Periodic QA/QC inspection and report.

- Full time QA/QC inspection and report.

- Façade fabrication QA/QC inspection and report.

- Façade raw materials production/suppliers QA/QC inspection and report.

- Production progress report.

- Other customized façade service.

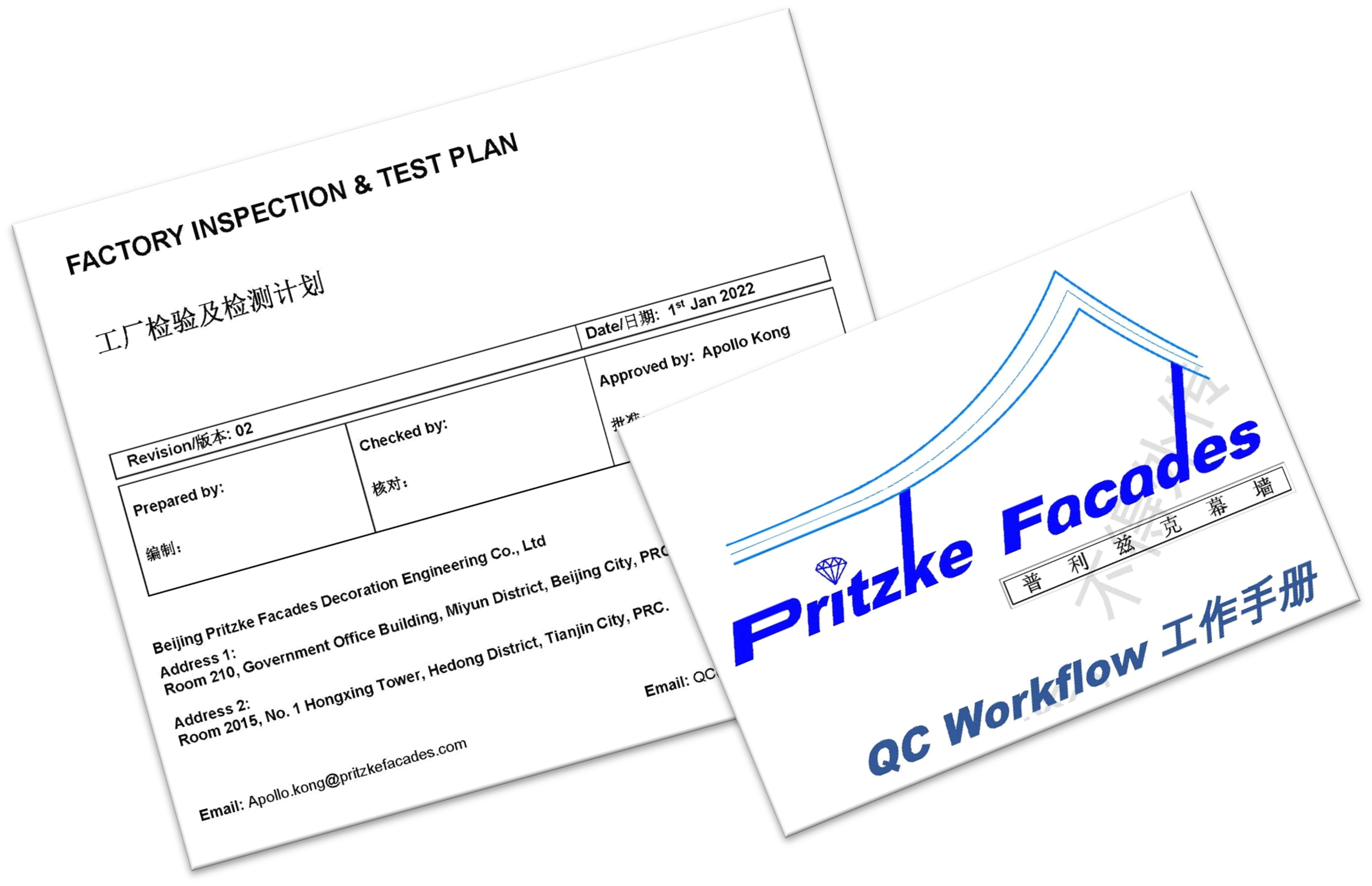

Pritzke Facades Quality Management System

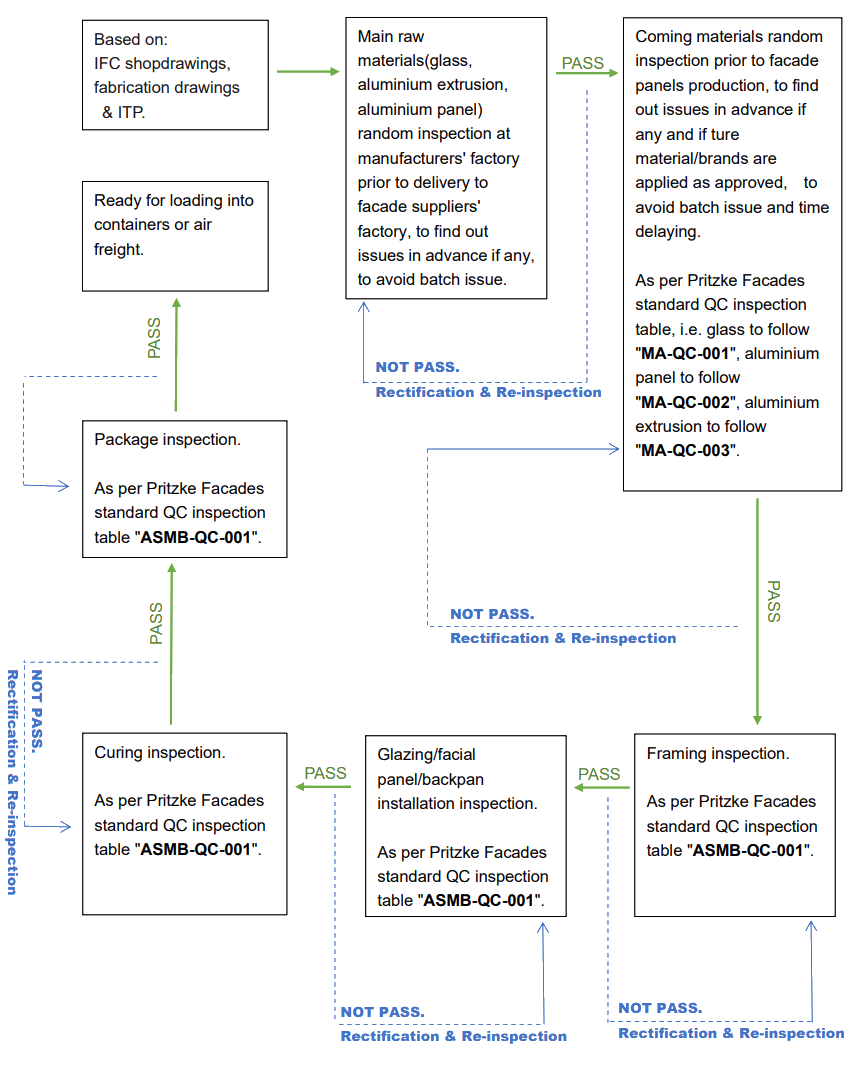

Pritzke Facades provide close-loop QM for each process, each product, each project. Not just for final finished products.

| QC engineers Qualification |

All experienced.

AAll dedicated.

Incorruptibility and self-discipline.

All QC staffs were recommanded by the

authoritative experts trust, must be trained and qualified and

passed Pritzke Faça internal requirement.

Average over 15 yrs experience in global

façade projects previously worked as QC directors/managers/masters

in CNYD, JANGHO, AVIC.

|

| Management Time Apportion |

80%~85% in QC and QM and work in workshop.

15%~20% in programmer tracking.

Could be adjusted based on client

instructions.

|

| Quality Management |

Inspect each production

stage from beginning to end for each panel, including raw material

inspection, machining, framing, glazing, cleaning, package, loading

containers.

|

| Shopdrawing Review. |

Shopdrawings for each

project reviewed by all QC engineers in Pritzke Facades, to

summarize key quality points and potential quality risk points.

|

| Factory production Drawings Review. |

Compare factory production

drawings against approved shopdrawings randomly, to ensure if

production drawing comply with approved shopdrawings.

|

| Package |

Ensure package sequence

comply with approved package plan and installation sequence.

|

| Loading container inspection |

Inspect each stillage, each

crate, each stillage.

|

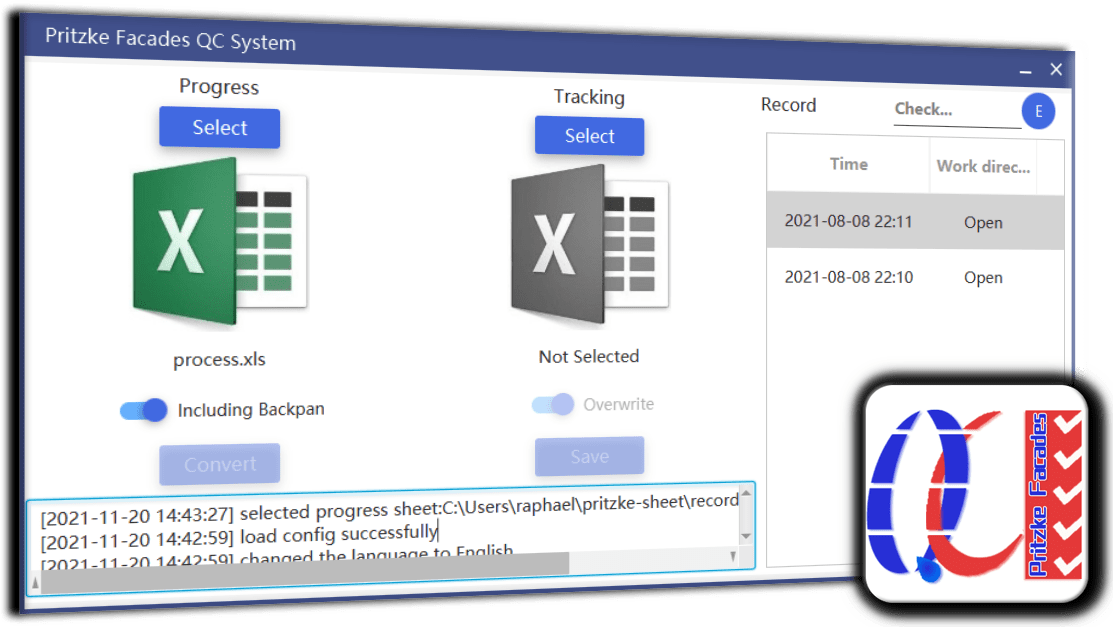

| Programmer Tracking |

Compare curent material arrival and

current production progress againt apporved programmer.

Raise production delay risk in time to

factory and client, and push and follow up.

To record each assembled panel status,

from machining, framing, backpan, glazing, package till shipped.

Same to bulk materials, subframes.

To record and reminder whether all

products in one floor have been fully shipped in time.

|

| Report submittion |

Daily QC report,including:

Daily production progress

report:

Weekly report, including:

|

Inspection Tools

Progress Tracking Software

Façade Production Quality Critical Control Point Inspection

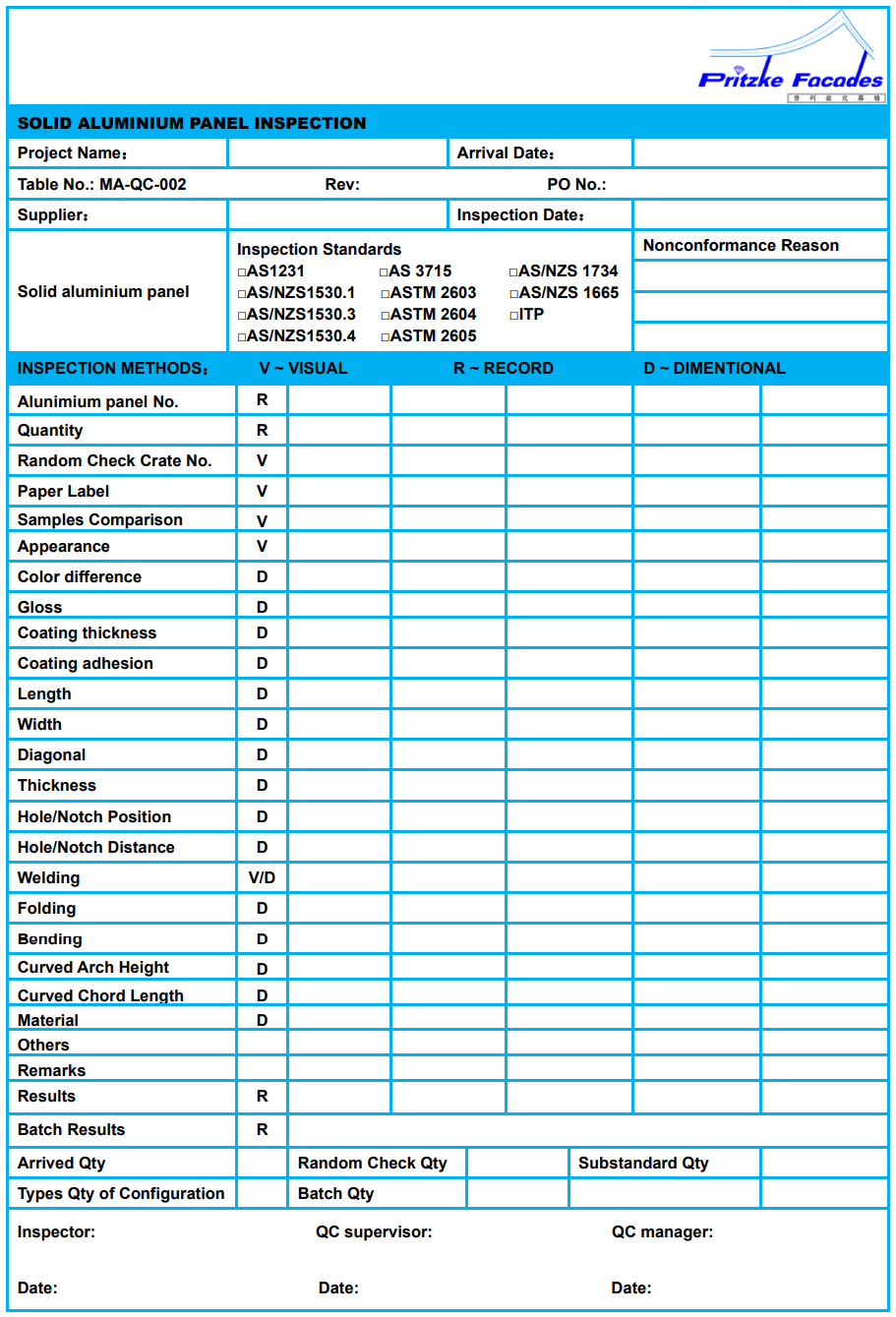

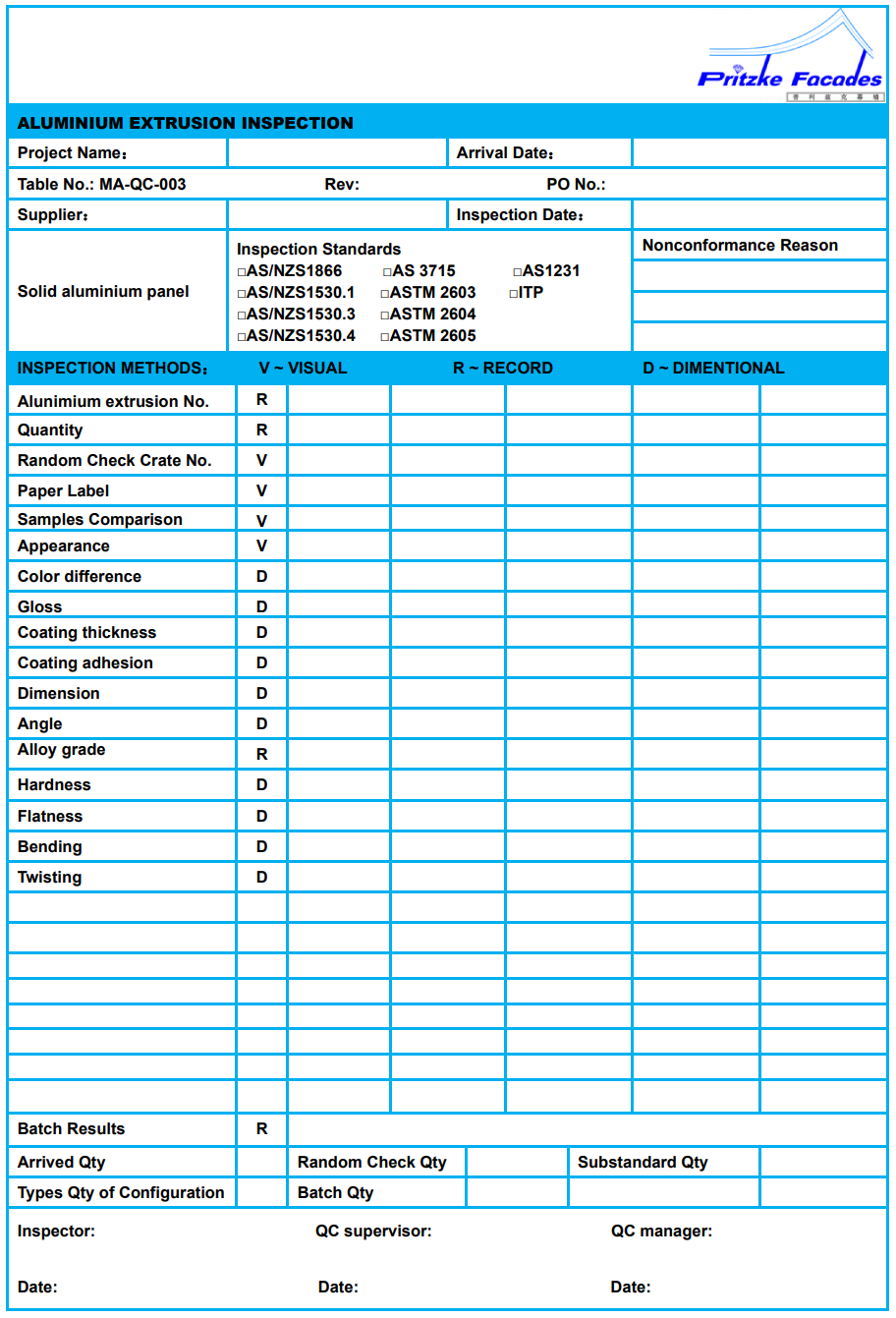

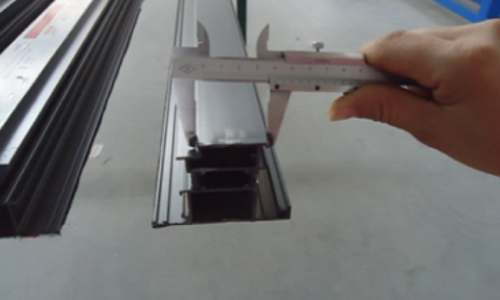

➢ Aluminium Extrusion & Aluminium Panel Coming Inspection.

Dim inspection

Wall Thk inspection

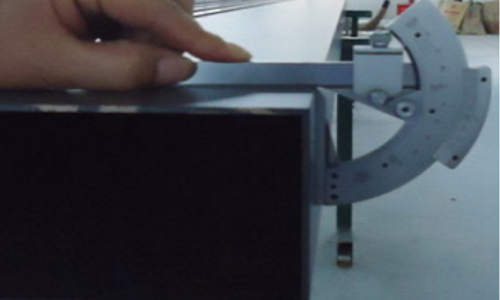

Angle inspection

Hardness inspection

Color inspection

Adhesion inspection

Film Thk inspection

Gloss inspection

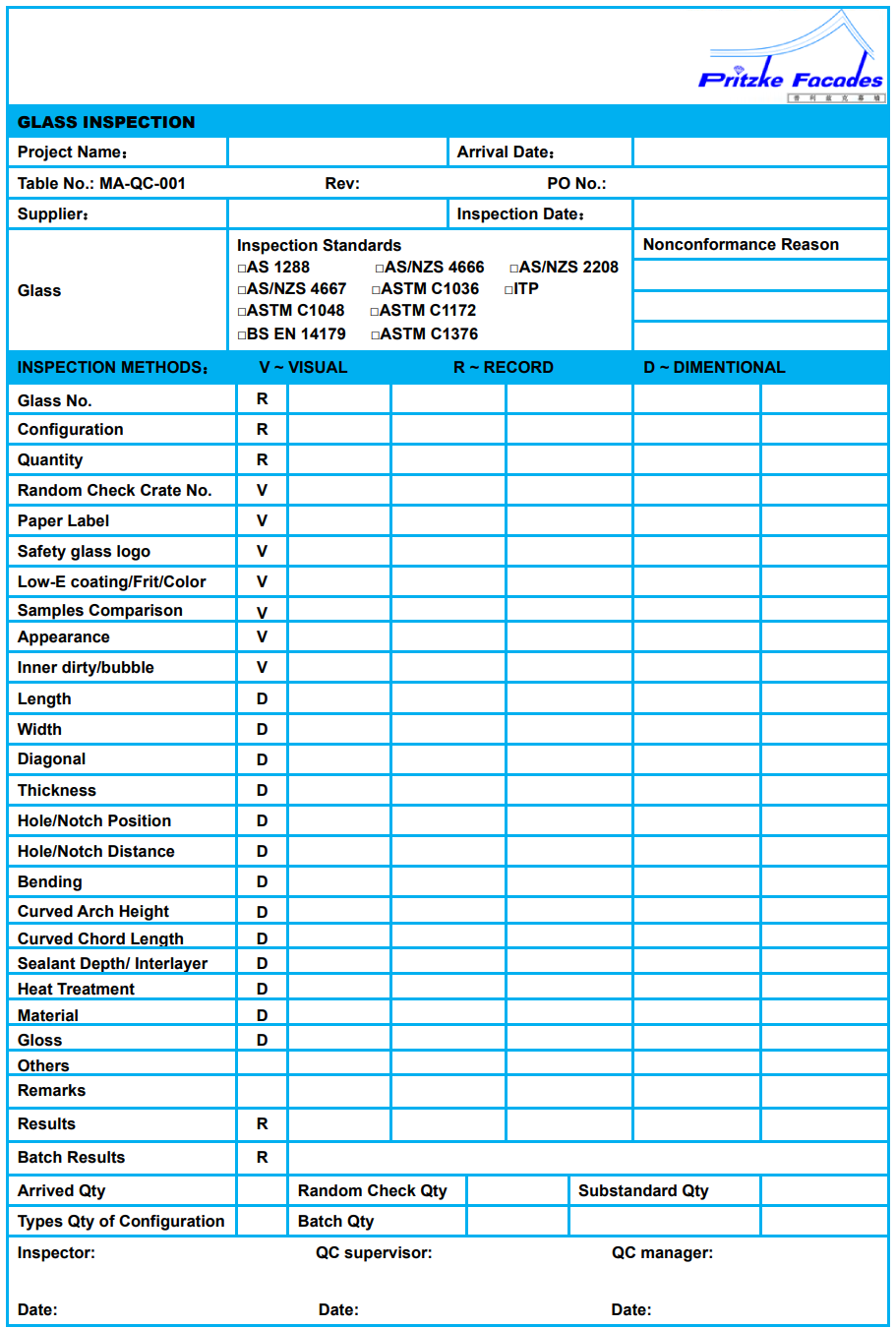

➢ Glass Coming Inspection.

Logo inspection

Low-e inspection

Color inspection

Sealant inspection

Dim inspection

➢ Machining Inspection.

Cutting length inspection

Cutting angle inspection

Tooth hole inspection

Holes inspection

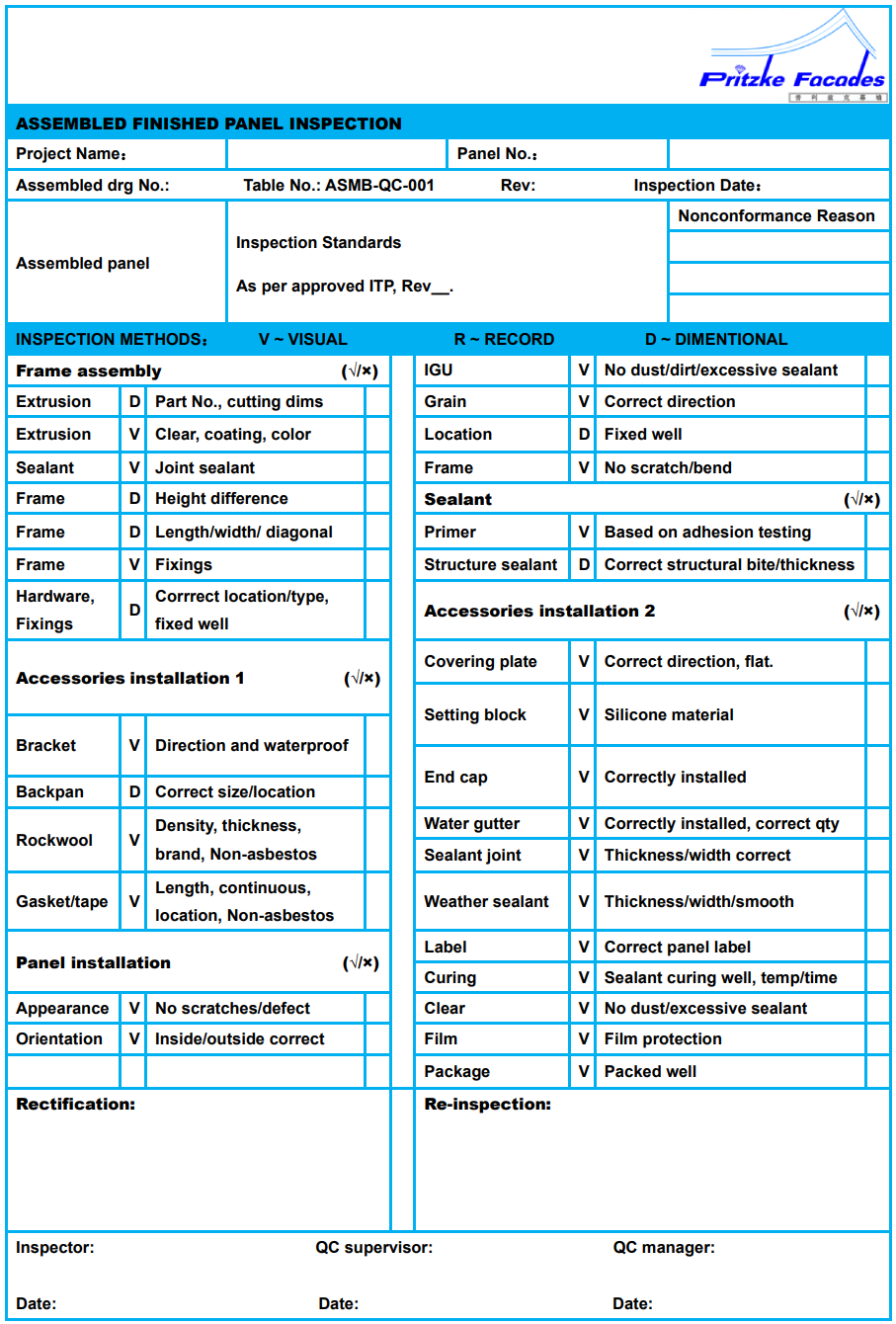

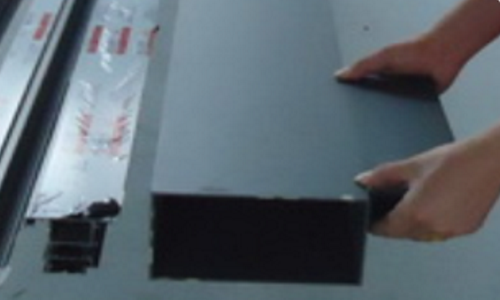

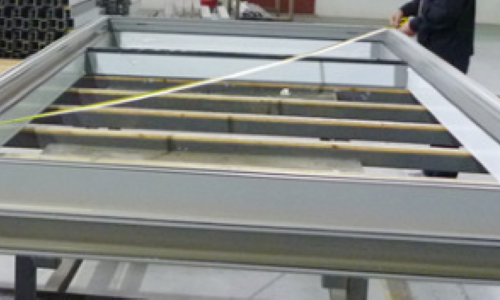

➢ Framing Inspection.

End clearance

End sealing

Screw sealing

Height difference inspection

Dim inspection

Gap Inspection

➢ Glazing Inspection.

Butterfly Test

Breaking Test

Peel Test

Double Clear Inspection

Primer Inspection

Structural Adhesion Inspection

Curing Humiture Inspection

Package Inspection